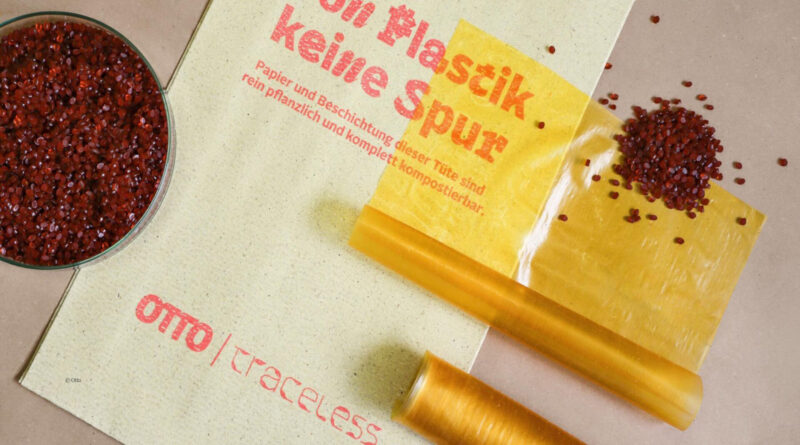

Compostable Shipping Bags “More Complex than Expected”

Online retailer Otto wants to deliver orders in shipping bags made from 100 percent plant-based material starting 2024. But the development of fully compostable shipping bags is proving more difficult than expected, according to Otto and partner Traceless.

In a joint announcement, Otto and Traceless say they will postpone the launch of compostable shipping bags made from film. Preliminary tests went well, they say, but the live test could not start because of difficulties. There were problems with the final bonding of the bags. The bonding of the Traceless material by heat and without glue was not successful. Now the parallel development of the existing prototype and a new one is to follow.

Otto packaging expert Karla Jabben explains: “We are making progress, but the development is more complex than expected. Actually, a larger pilot test was supposed to start a few weeks ago – with a bag made of a composite material consisting of Traceless and grass paper. However, during an internal preliminary test, which we always carry out for such projects, unexpected difficulties arose. So, we decided to postpone the live test and put more time into development.”

Test phase to start in 2024

Traceless has developed the plant-based material of the coating. Anne Lamp, co-founder of Traceless explains, “But that’s not the end of the story – coating, converting, printing, folding, and gluing also need to be solved. Our aspiration is that companies can use our material on existing machines. That works – but not right away, of course, because the machines have been optimized for conventional plastics for decades.” The company also wants to ensure that all processing steps are sustainable, she says. “We found an environmentally friendly solution for the printing, the folding also worked, and it was only at the very last step that things got tricky: at the last gluing point. This step was not quite ready for series production in the last prototype. The fact that we were, therefore, not yet able to go into the test phase is, of course, a disappointment.”

Nevertheless, both companies assure that they are still committed to the project. In 2024, they say, they will be ready for testing. “In cooperation with partners, we will now test film production at various scales and gradually optimize the traceless material, including further processing into a bag. In parallel, the variant of the current prototype made of coated paper also remains an option that we are keeping an eye on,” says Lamp. In this way, various solutions are being pursued at the same time.