Federal Minister for the Environment, Nature Conservation and Nuclear Safety promotes innovative printing concept for corrugated board

Schumacher Packaging GmbH plans to implement a new plant for producing and printing corrugated board. The pilot project at the site in Greven, North Rhine-Westphalia, is being supported by the Federal Ministry for the Environment, Nature Conservation and Nuclear Safety because it is an important contribution to efficiency of resource use, saving large quantities of paper, ink and water.

The Bavarian company Schumacher Packaging GmbH is getting more than EUR 2.8 million from the Federal Ministry’s Environmental Innovation Programme for implementing the project. In the current state of the art, two separate plants are required to produce colour printed packaging made of corrugated board, and so far corrugated board has been produced in one plant and the outer cover has been printed in a second plant. The ink is applied to the board by special rollers, resulting in relatively large quantities of ink, water and sludge. The aim of this project is to integrate the process steps of corrugated board production, printing and cutting in a single plant, using a high-performance digital printing system in which the paper is printed directly on the corrugator before being further processed into corrugated board. This also reduces paper consumption.

In contrast to the current printing process, the digital printing process is a non-contact printing process in which the ink is applied directly to the paper to be printed using an electrophotographic printing system. The print image is transferred to the printing press under computer control, which eliminates time-consuming cleaning. As a result, consumption of water and the amount of heavy metal-containing toxic sludge are also significantly reduced.

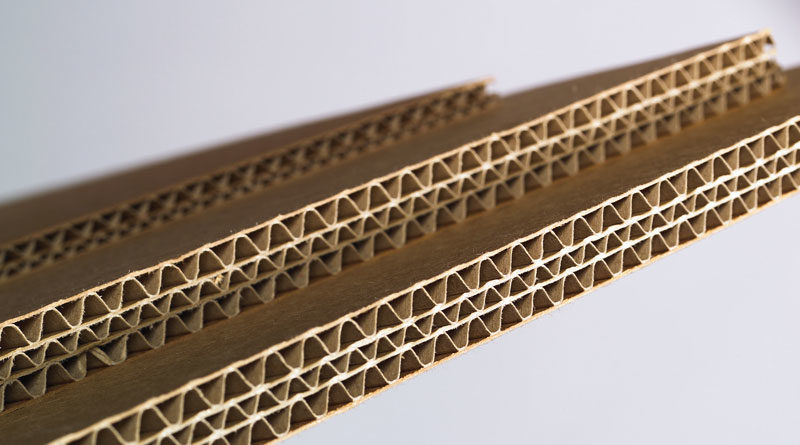

Corrugated board is one of the most frequently used packaging materials, and Germany alone produces more than four million tons of corrugated board a year. If the project is successful, a high multiplier effect can be assumed for the entire printing industry. The Environmental Innovation Programme promotes the first large-scale application of an innovative technology. Projects must go beyond the state of the art and should have a demonstration character.

“Digital multicolour printing on white outer covers is similar to offset printing. But digital printing can for the first time also print brown outer covers in many colours – which was not possible in flexographic printing due to the high plate costs,” according to the company, which notes that contactless ink application in digital printing even makes it possible to print any desired design on flute packaging. The corrugated flute also gives the motif a slight 3D effect.

Corrugated board is as versatile as the goods and products shipped in it. That’s why there are different designs depending on the product – the paper is selected to suit the intended use. “Corrugated board is versatile, flexible and can be used anywhere. Corrugated board is easy to print and can range from a simple brown box to a high-gloss finish display in all shapes and colours. It is environmentally friendly, easy to dispose of, and with an average of 80 per cent recycled content, it’s a poster child recycling product,” as the corrugated board industry association explains.