BASF and Henkel Collaborate

In collaboration with BASF, Henkel aims to replace fossil raw materials with renewable raw materials

over the next four years with the help of the so-called „biomass balance“ process. This applies to

most of Henkel’s consumer goods products manufactured in Europe in the Laundry & Home Care and

Beauty Care segments.

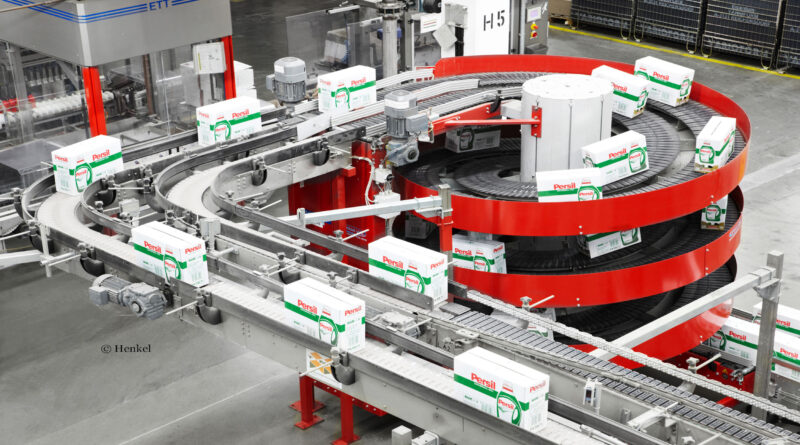

Cleaning and care brands such as Persil, Pril, Fa, and Schauma will thus reduce their carbon footprint

and save a total of around 200,000 metric tons of CO2 emissions, Henkel says. Through the

cooperation with BASF, the fossil raw materials for around 110,000 metric tons of ingredients per

year will be replaced by renewable raw materials, it says. There was already a successful pilot

project with Henkel’s Love Nature cleaning and laundry detergent brand in 2021.

„We are pleased to build on our long-standing collaboration with BASF and significantly increase the

share of biomass in the value chain of our products, which are used by millions of people around the

world every day,“ says Carsten Knobel, CEO of Henkel. „To drive climate protection forward, we

need to fundamentally make our business model more sustainable. We therefore want to

continuously improve our processes, products, and raw material use with a view to a resourceefficient, climate-neutral future. Integrating BASF’s biomass balance approach into our supply chain

is an important step in this direction.“

„I am very proud that Henkel is honoring BASF’s efforts to offer products with a low carbon

footprint,“ said Dr. Martin Brudermüller, Chairman of the Board of Executive Directors of BASF. „We

are equally proud to support such an innovative brand manufacturer that is a true pioneer in

offering end consumers more sustainable solutions of this magnitude. The project demonstrates

both companies‘ commitment to a sustainable future.“

BASF’s biomass balance approach replaces fossil raw materials with renewable raw materials as

early as the first steps of chemical production. The amount of biobased raw materials is then

allocated to specific sales products using a certified calculation method. BASF has established a closed control chain, from the renewable raw materials used to the end product. TÜV Nord assists in the practical implementation and confirms in accordance with the REDCert2 certification scheme that BASF replaces the required quantities of fossil raw materials for the biomass-balanced product with renewable raw materials.